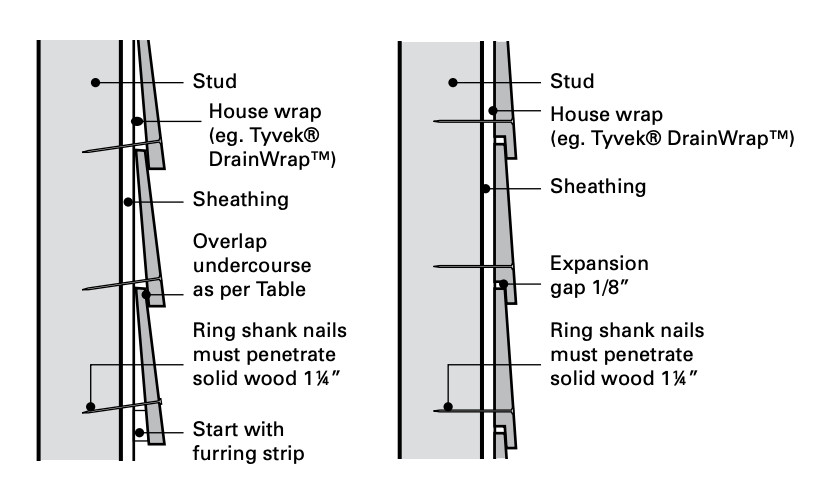

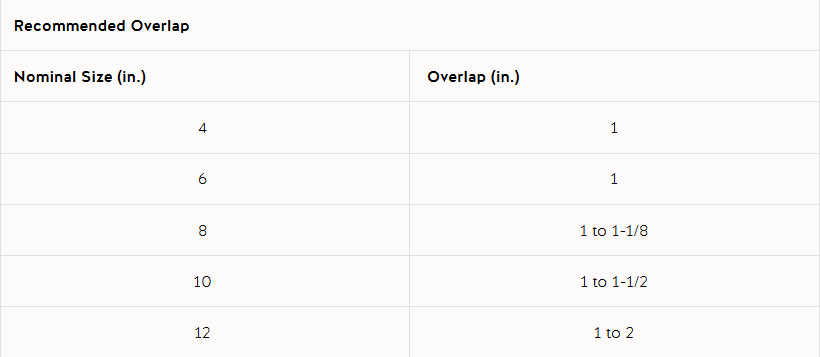

Spacing for the siding should be laid out beforehand. The number of board spaces between the soffit and bottom of the lowest piece of siding at the foundation should be such that the overlap is as per the table.

Start with the bottom course using a furring strip to support the lower edge. Each succeeding course overlaps the upper edge of the previous one by a minimum of 1 inch. Rabbeted patterns are self-spacing, but leave 1/8 inch expansion clearance. Where possible, the bottom of the board that is placed across the top of the windows should coincide with the window cap.

Bevel siding should be face nailed to studs with 1-1/4 inch penetration into solid wood using one nail per piece spaced at a maximum of 24 inches on center. Place nail just above the overlap. Take care not to nail through the overlap of two pieces.

Do not reduce the siding overlap recommendations given in the installation sections of this publication. Doing so could result in damage from wind-driven water. Use the larger overlaps for unseasoned sidings to allow for shrinkage and expansion. Take care not to overdrive fasteners when using larger overlaps. Butt joints between boards should be staggered and meet on studs. Fit siding snugly to other pieces and to trim.

This primarily applies to bevel siding and board and batten applications (a design that combines wider vertical planks with narrower strips of material that cover the vertical joints).

For bevel siding, install the nail at the proper angle

Adjust your nail angle to be perpendicular to the face of the bevel siding (not the wall itself). This allows the nail to be flush with the surface of the wood (if you drive your nail perpendicular to the wall, the nail will end up half countersunk).

Field cuts must be sealed or stained

The end grain of cedar will absorb up to 250 percent more moisture than the other surfaces. Failure to seal the end cuts means that they are exposed to moisture, which will cause adhesion problems for any primer, solid stain, or paint applied thereafter.

Use ring shank siding nails that are high quality and corrosion-resistant

Using a high quality (preferably stainless steel) nail is always the best option. The nails should be long enough to penetrate solid wood by a minimum of 1 ¼ inch.

Siding should be pre-finished on all six sides before going on the wall

Pre-priming or pre-finishing each side (and end) of the siding helps to balance the absorption of moisture, creating a more stable product that is more likely to stay flat on the wall.